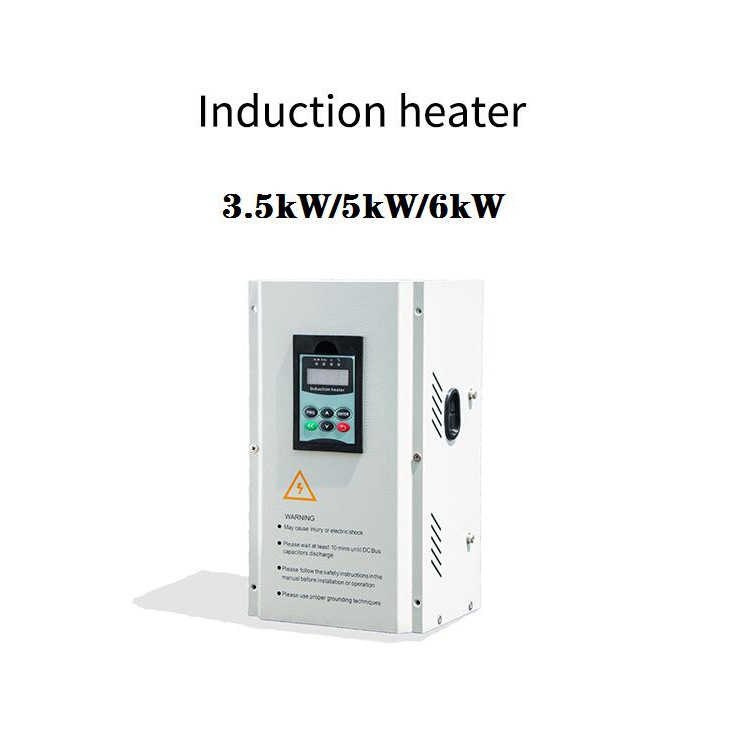

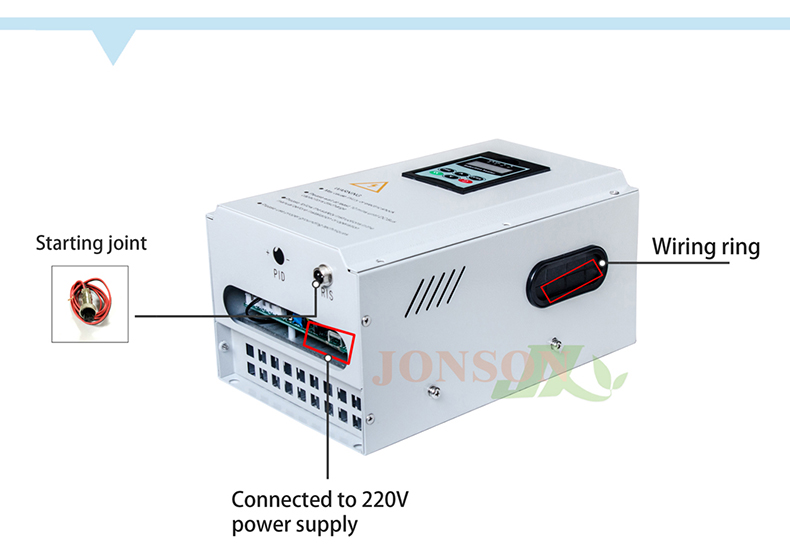

8KW/220V Induction Heater

Product Details

Dimensions

The key to choosing an inductionheater depends on these four points

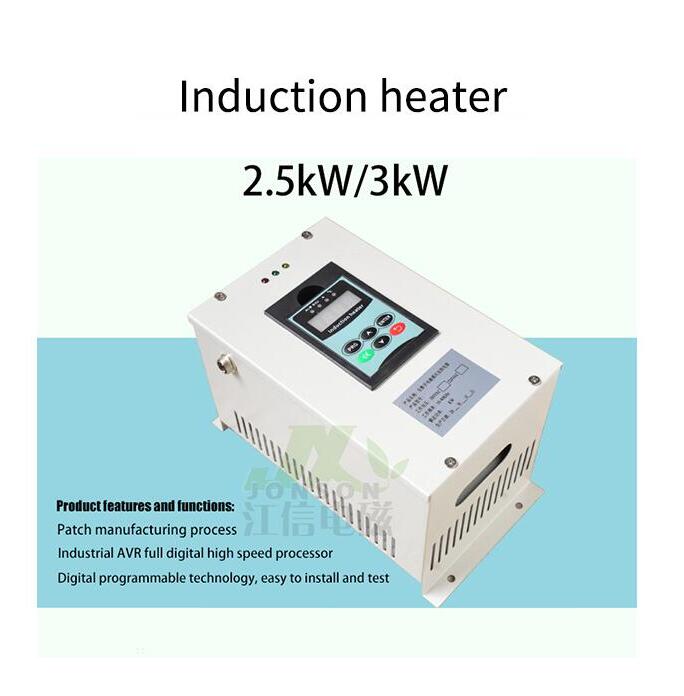

1,Specialization: DSP high-speed operation control, digital programmable technology, high-speed optocoupler drive, open hardware architecture

2,Stable performance: The half-bridge IGBT module is used as the main circuit structure, which can save power by 30% ~ 80%, and the thermal efficiency can reach 95%, which can be customized:

3,Worry-free after-sale: one year warranty, professional technical staff guidance, lifetime cost maintenance of wearing parts, after-sales customer service one-to-one tracking service:

4,Quality assurance: 15 years of careful development, EU CE certification, ISO9001 quality management certification

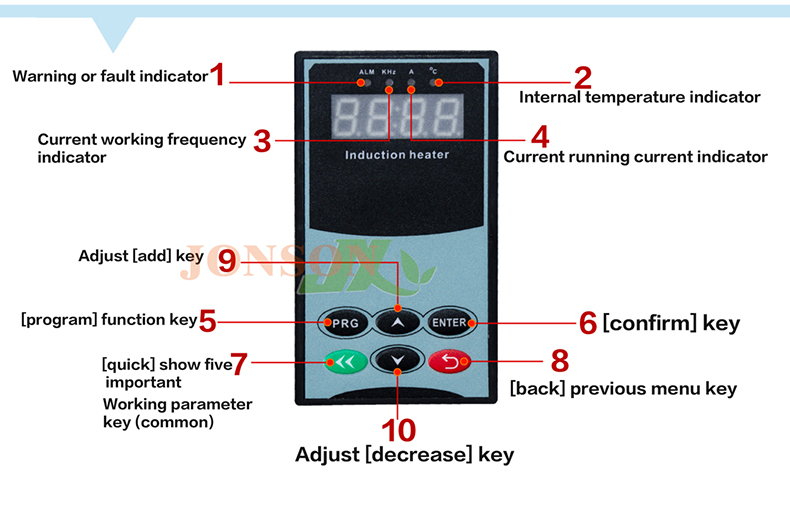

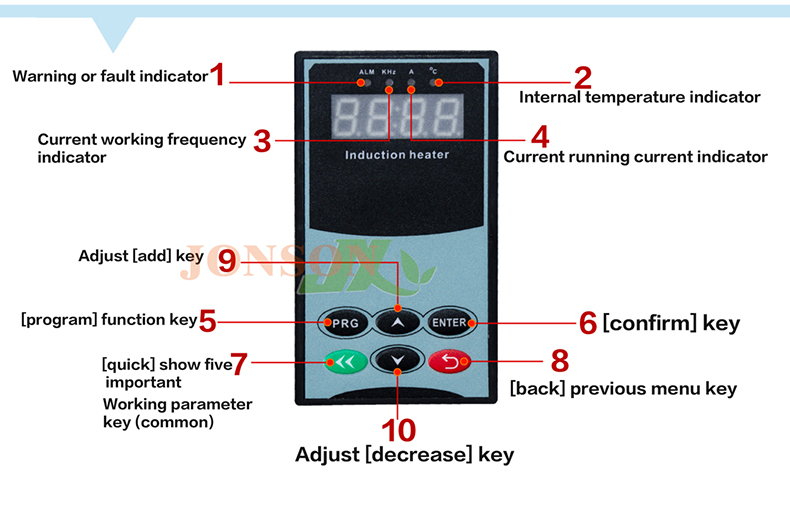

Operation panel description

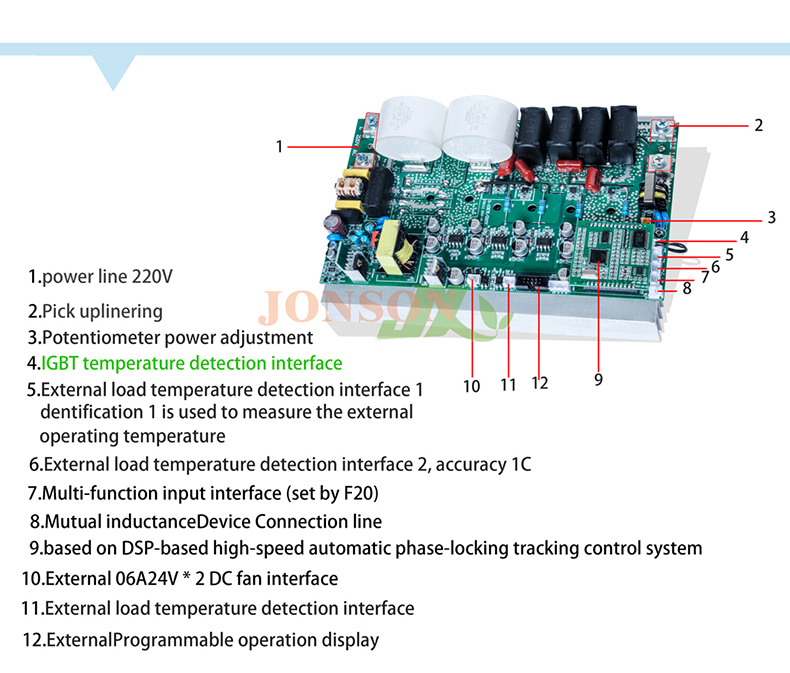

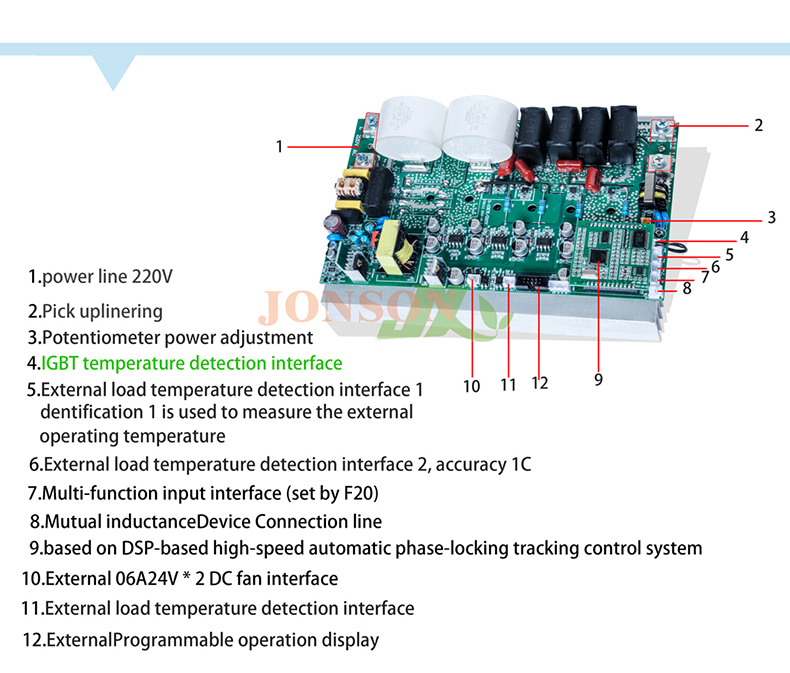

Internal structure and wiring diagram

NamePerformance parameter

rated power:Single-phase 8KW

Rated input current:30-36 (A)

Rated output current:50-75 (A)

Rated voltage frequency:AC 220V/50Hz

Voltage adaptation range:constant power output at 300 ~ 400V

Adapt to ambient temperature:-20ºC~50ºC

Adapt to environmental humidity:≤95%

Power adjustment range:20% ~ 100% stepless adjustment(That is: adjustment between 0.5 ~ 8KW)

Heat conversion efficiency:≥95%

Effective power:≥98%(Can be customized according to user needs)

working frequency:5~40KHz

Main circuit structure:Full bridge series resonance

Control System:DSP-based high-speed automatic phase-locking tracking control system

Application mode:Open application platform

monitor:Programmable digital display

start time:<1S

Instantaneous overcurrent protection time:≤2US

Power overload protection:130% instantaneous protection

Soft start mode:Fully electrically isolated soft start heating / stop mode

Support PID adjustment power:Identify 0-5V input voltage

RS485 communication:moddbus RTU standard communication protocol

Adaptive coil parameters:8KW 10 square line, length 30m, inductance 100 ~ 120uH

Description

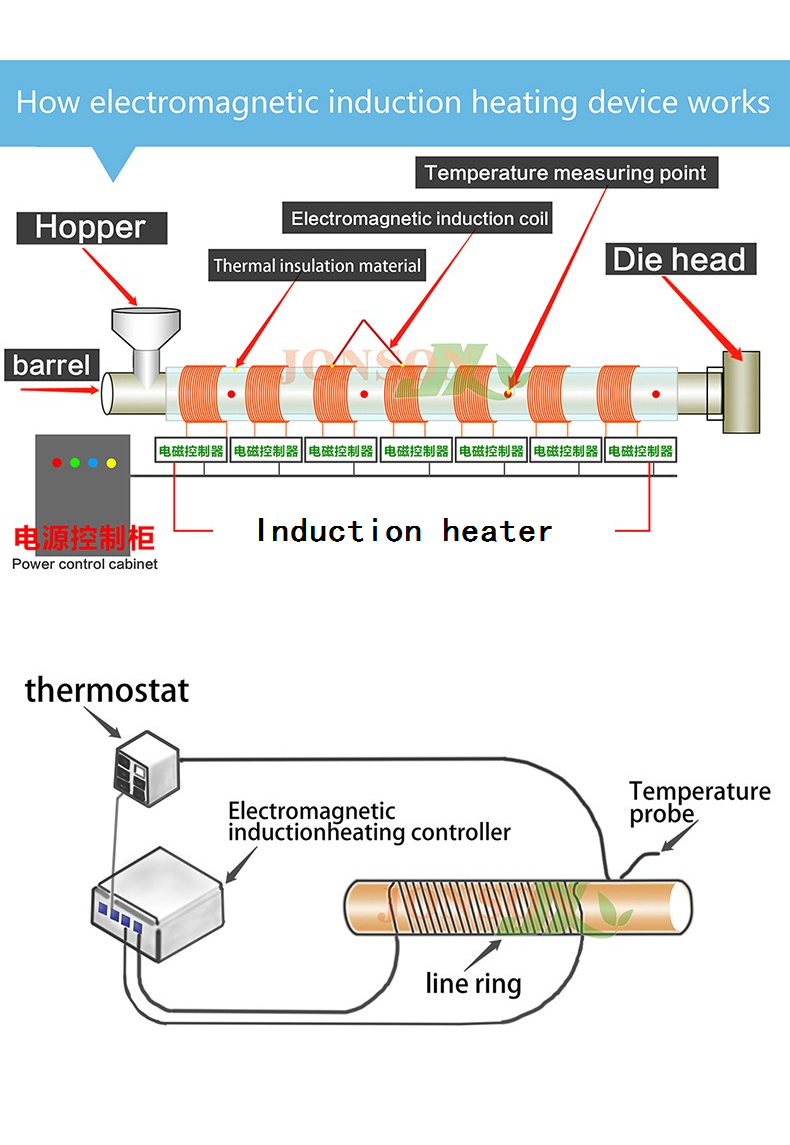

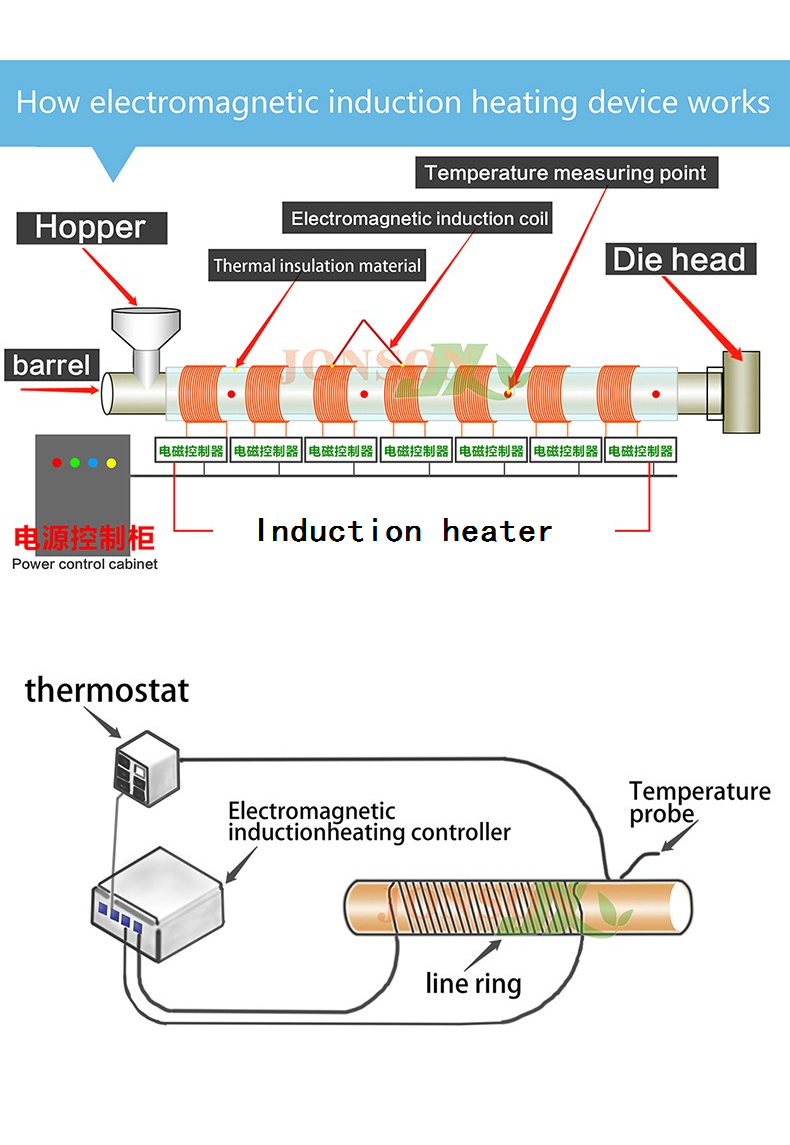

The control board of induction devices has been specially designed to save energy in the heating needs of injection molding, extrusion machines and cable production machines as a result of 15 years of R&D.

After the installation of the product, injection molding machine etc. Energy savings of 30% to 80% will be achieved in the electrical energy required to heat the such devices. Therefore, induction heating devices are ideal heating equipment especially for specified machines.

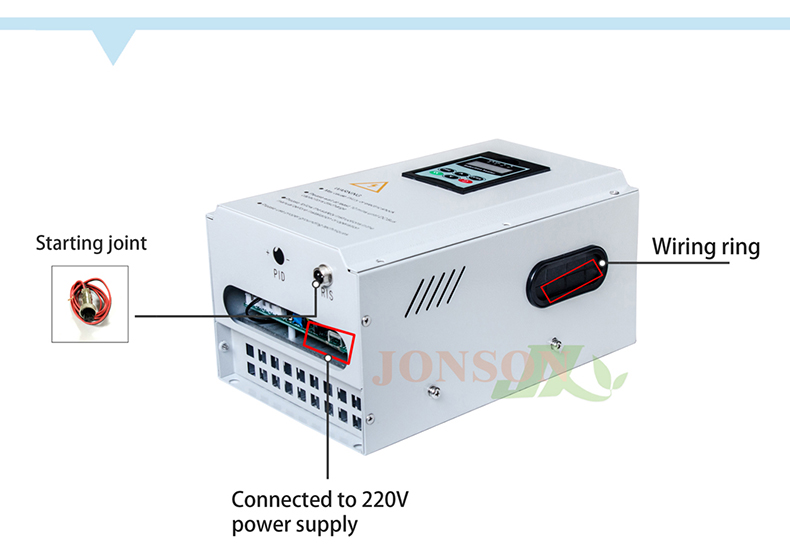

1. Power line 220V

2. Pick uplinering

3. Potentiometer power adjustment

4. IGBT temperature detection interface

5Externalload temperature detection interface 1dentification 1 is used to measure the external operating temperature

6. External load temperature detection interface 2, accuracy 1C

7. Multi-function input interface (set by F20)

8.MutualinductanceDevice Connection line

9. Based on DSP-based high-speed automatic phase-locking tracking control system

10.External 06A24V* 2 DC fan interface

11. External load temperature detection interface

12. External Programmable operation display