10kW/15kW/380V Induction Heater

How does induction heater save 30%-70% energy on plastic machinery?

1. Compared with resistance heating, the induction heater has an extra layer of the insulation layer, and the heat energy utilization rate increases.

2. Compared with resistance heating, induction heater directly ACTS on the material tube heating, reducing heat transfer heat loss.

3. Compared with resistance heating, the heating speed of the induction heater is more than one quarter faster, which reduces the heating time.

4. Compared with resistance heating, the heating speed of the induction heater is fast and the production efficiency is improved. The motor is in a saturated state, which reduces the power loss caused by high power and low demand.

The above is the traditional resistance heater and induction heater advantages and disadvantages comparison, is it clear?

So, do you want to continue using traditional resistance heaters?

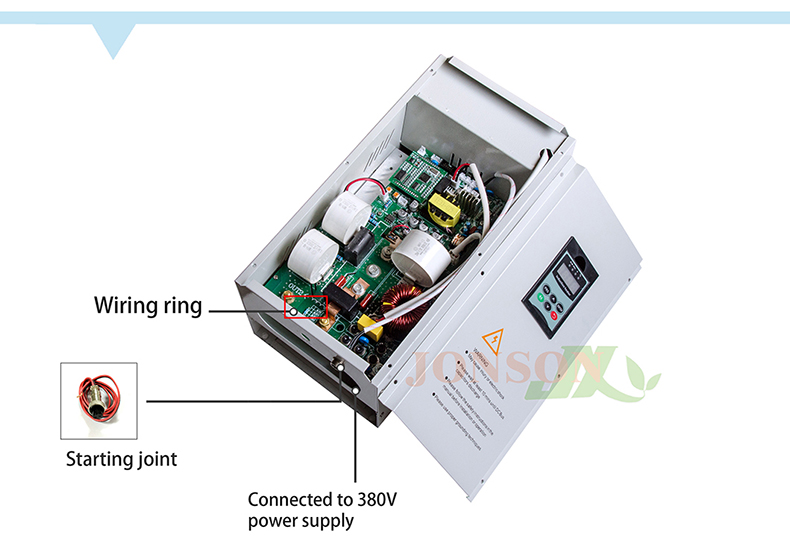

10kW/15kW/380V induction heater Basic Info:

Model NO.:JS1300-10/15

Type:Induction Heating Machine

Certification:CE, ISO, RoHS

Structure:Wall-Mounted

Brand:Jonson

Rated Power:10kW/15kW

Power Adjustment Range:20%~100%

Rated Voltage:380V

Voltage Adaptation Range:300V~400V

Adapt to Ambient Temperature:-20 Degrees Celsius to 50 Degrees Celsius

Adapt to Environmental Humidity:Less Than or Equal to 95%

Net Weight:7.3kg

Trademark:Jonson

Transport Package:Carton / Wood Frame

Specification:356mm*178mm*178mm

Origin:Guangdong Province, China

HS Code:8514400090

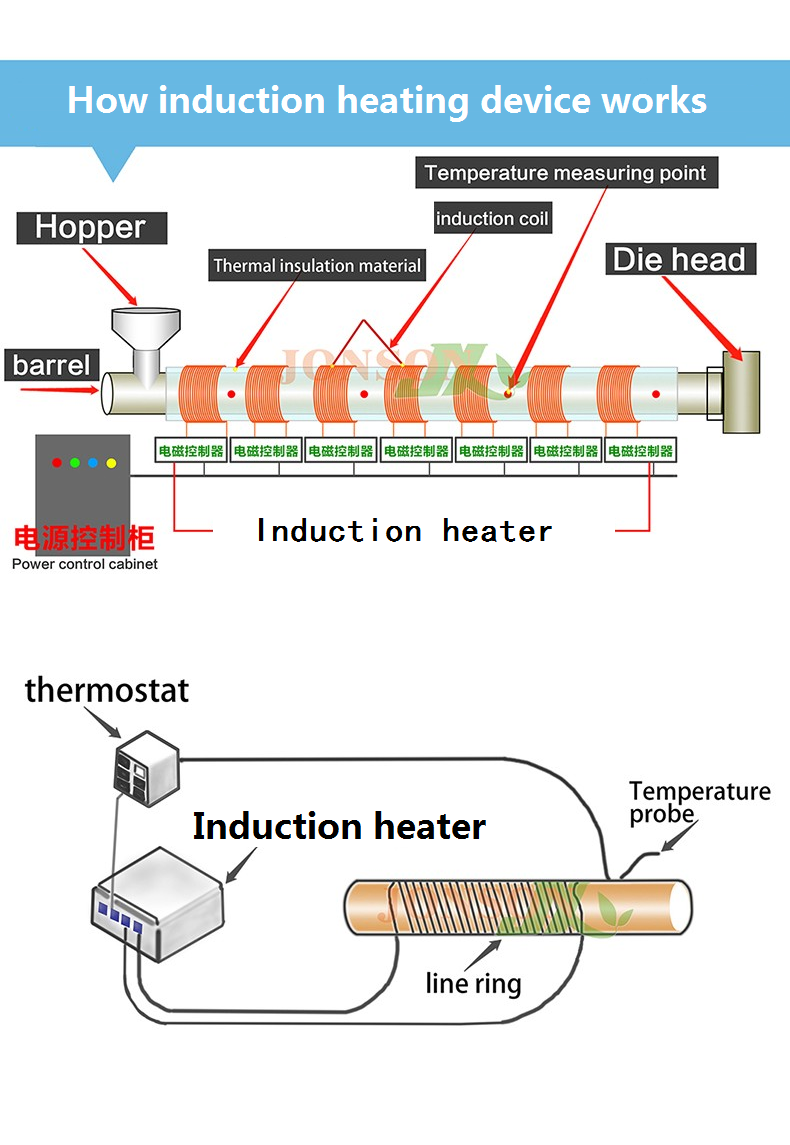

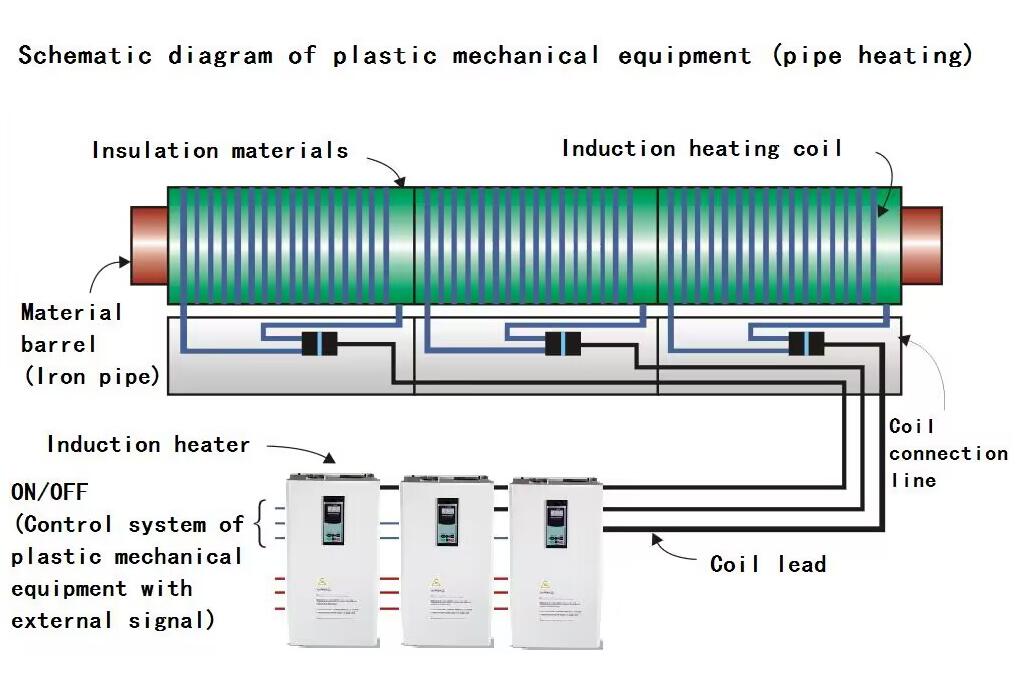

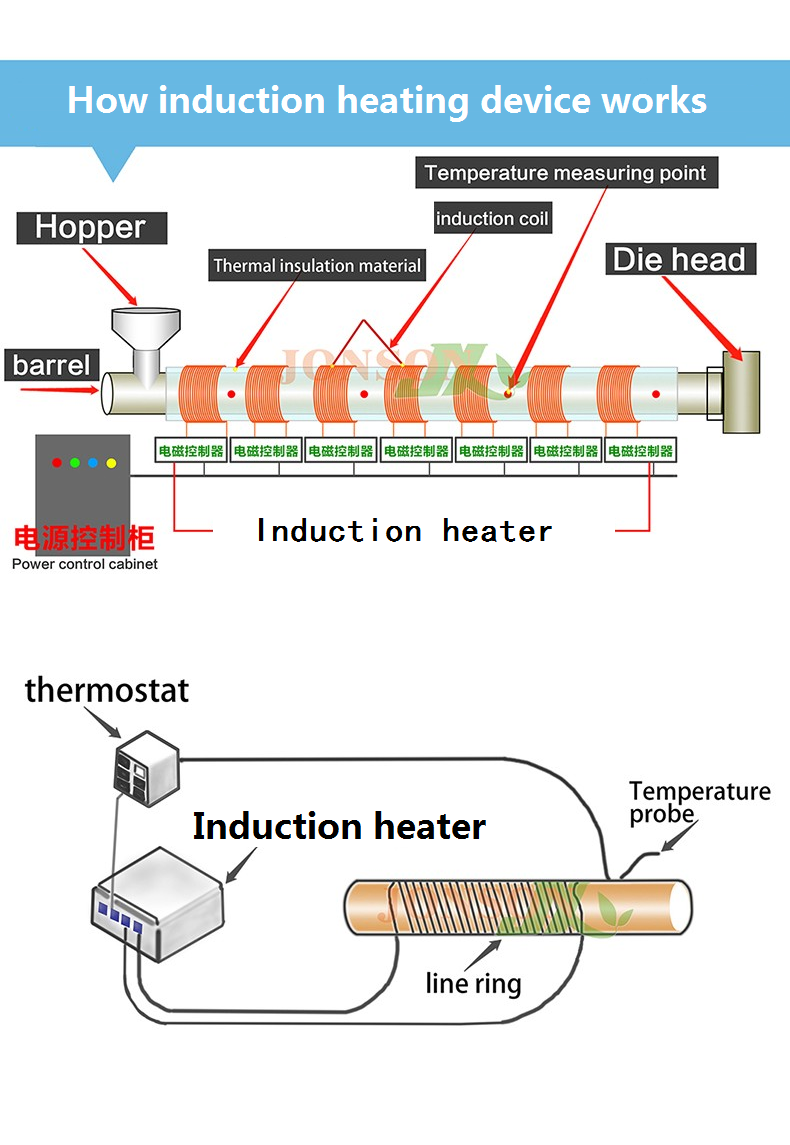

working principle:

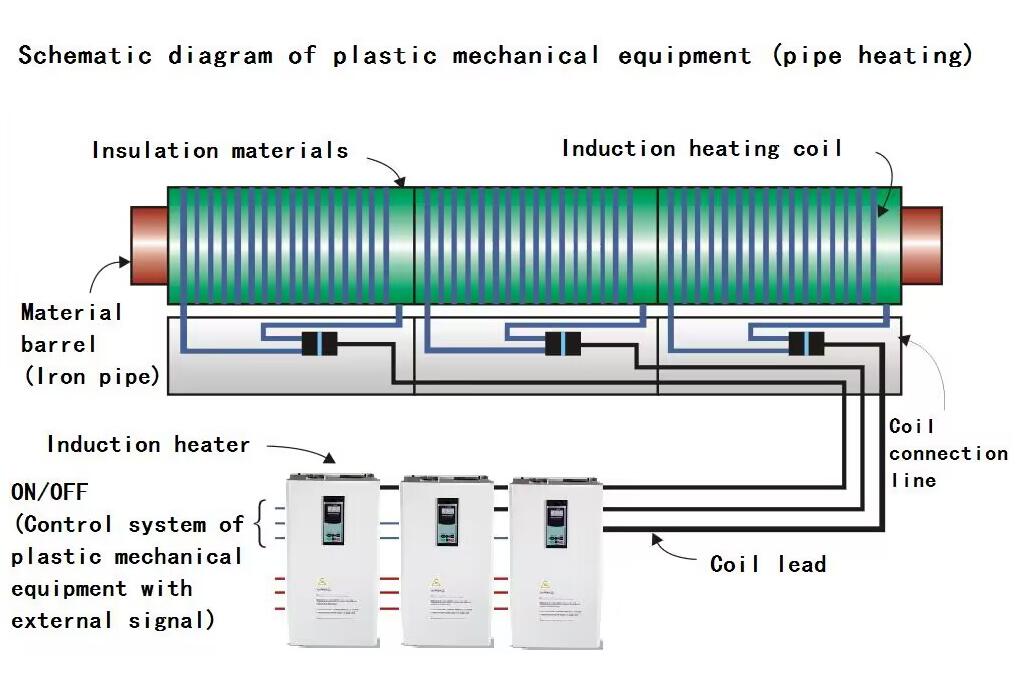

An Induction heater is a device that converts electrical energy into heat energy by means of Induction heater. Induction heater will be 220V/380V, 50/60 hz alternating current (ac) by the rectifier circuit rectifier into direct current (dc), through the control circuit converts direct current (dc) into different frequency voltage, high speed change of high-frequency electric current flows through the coil produces high speed change of alternating magnetic field, When the alternating magnetic field lines in the magnetic field pass through the magnetically permeable metal (iron, cobalt, nickel) material, countless small eddy currents will be generated in the metal body.The metal material itself generates heat at a high speed, thereby achieving the purpose of heating the contents of the metal material barrel.

NamePerformance parameter

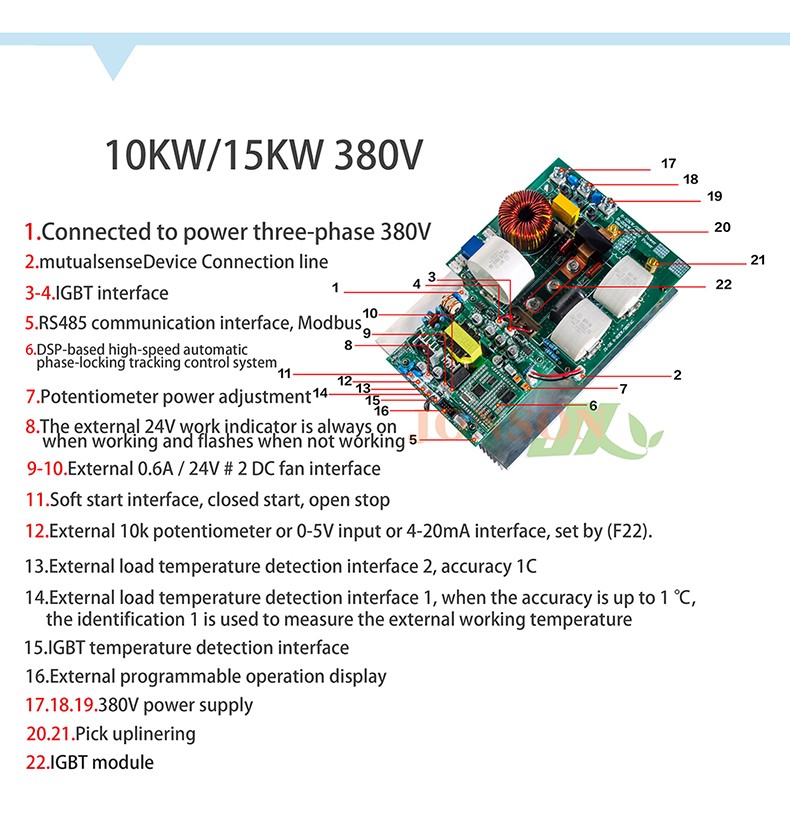

rated power:10KW/15KW Three-phase 380V

Rated input current:10KW (14-15A) 15KW (20-22A)

Rated output current:10KW (50-60A) 15KW (60-70A)

Rated voltage frequency:AC 380V/50Hz

Voltage adaptation range:constant power output at 300 ~ 400V

Adapt to ambient temperature:-20ºC~50ºC

Adapt to environmental humidity:≤95%

Power adjustment range:20% ~ 100% stepless adjustment(That is: adjustment between 0.5 ~ 10/15KW)

Heat conversion efficiency:≥95%

Effective power:≥98%(Can be customized according to user needs)

working frequency:5~40KHz

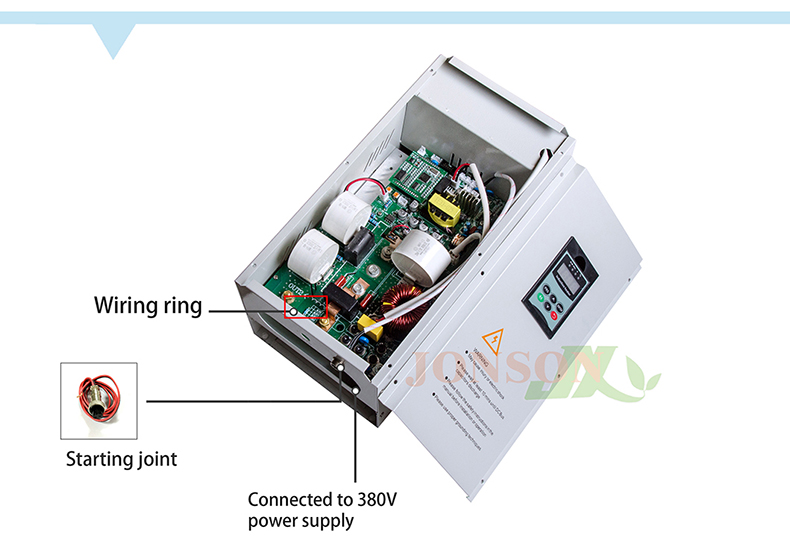

Main circuit structure:Half-bridge series resonance

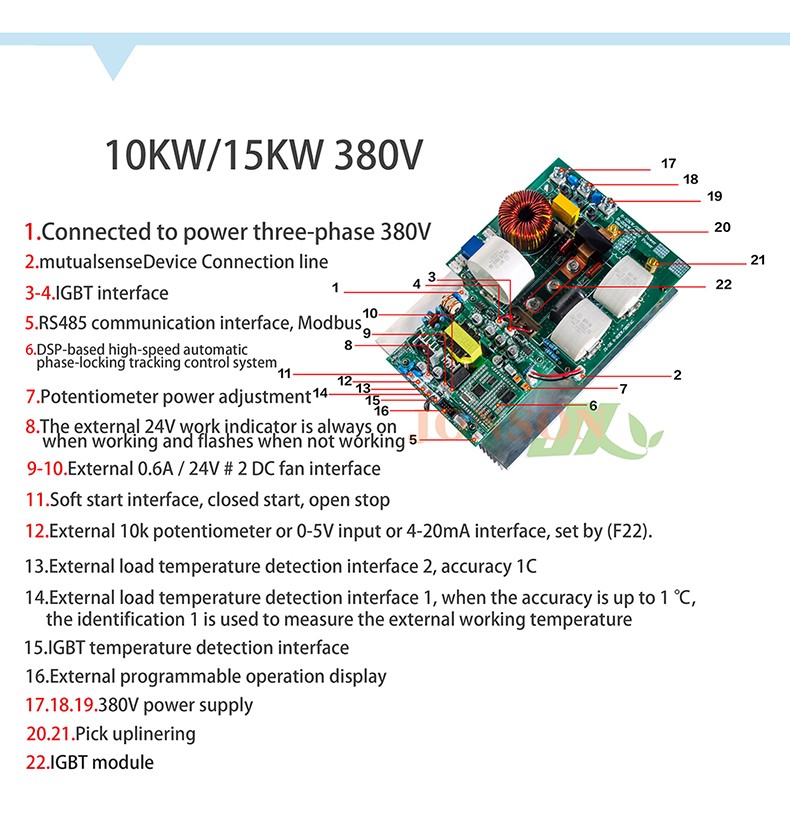

Control System:DSP-based high-speed automatic phase-locking tracking control system

Application mode:Open application platform

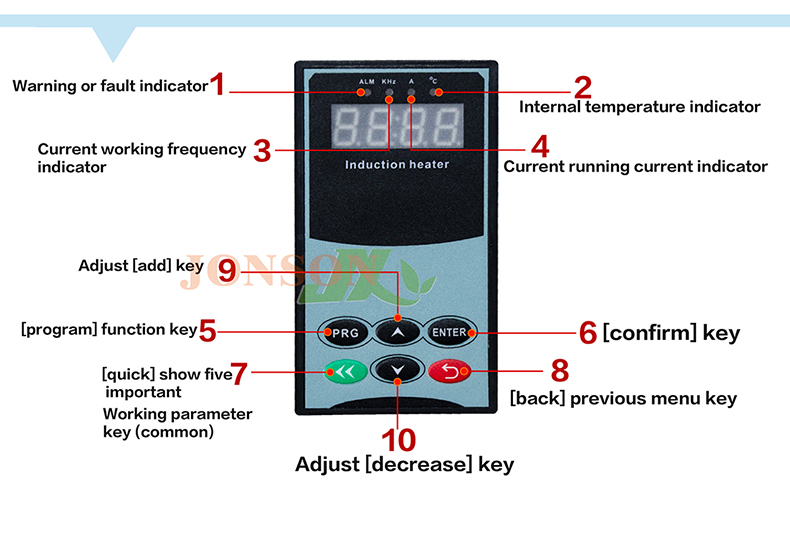

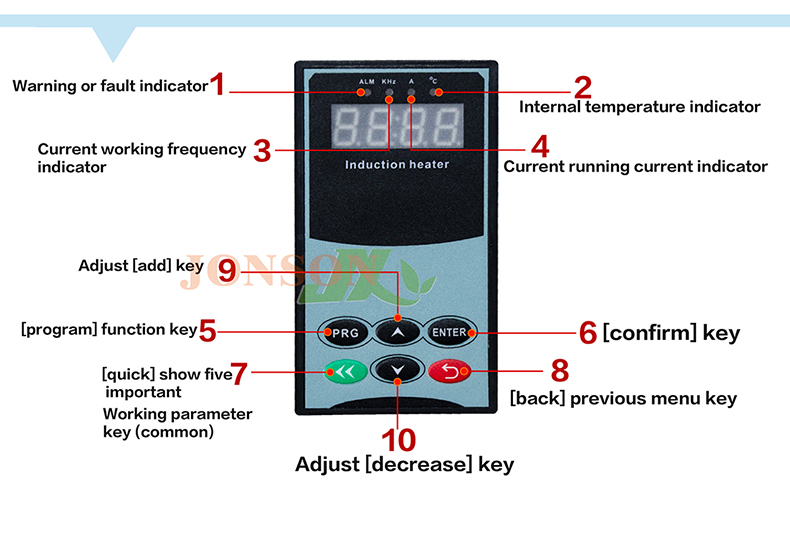

monitor:Programmable digital display

start time:<1S

Instantaneous overcurrent protection time:≤2US

Power overload protection:130% instantaneous protection

Soft start mode:Fully electrically isolated soft start heating / stop mode

Support PID adjustment power:Identify 0-5V input voltage

Support 0 ~ 1000 ºC load temperature detection:Accuracy up to ± 1 ºC

Adaptive coil parameters:10KW 10 square line, length 30~35m, inductance 150 ~ 180uH

15KW 16 square line, length 25~30m, inductance 110 ~ 140uH

Coil to load distance(Thermal insulation thickness):20-25mm for circle, 15-20mm for plane, 10-15mm for ellipse and within 10 mm for super ellipse

Description

The key to choosing an Induction heater depends on these four points

1,Specialization: DSP high-speed operation control, digital programmable technology, high-speed optocoupler drive, open hardware architecture

2,Stable performance: The half-bridge IGBT module is used as the main circuit structure, which can save power by 30% ~ 80%, and the thermal efficiency can reach 95%, which can be customized:

3,Worry-free after-sale: one year warranty, professional technical staff guidance, lifetime cost maintenance of wearing parts, after-sales customer service one-to-one tracking service:

4,Quality assurance: 15 years of careful development, EU CE certification, ISO9001 quality management certification