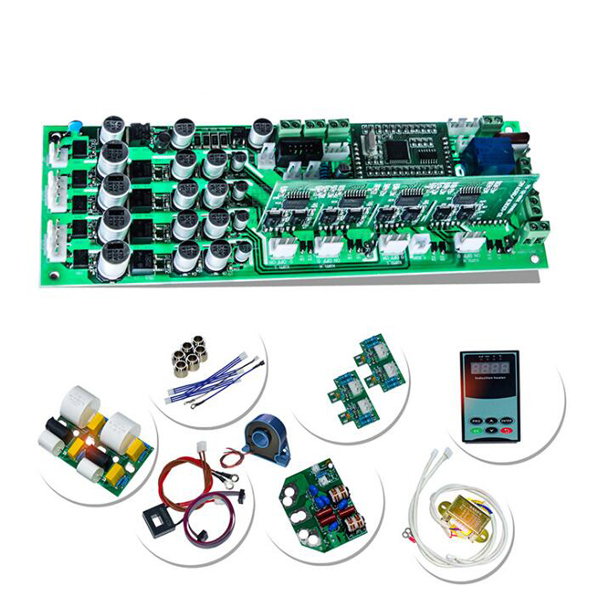

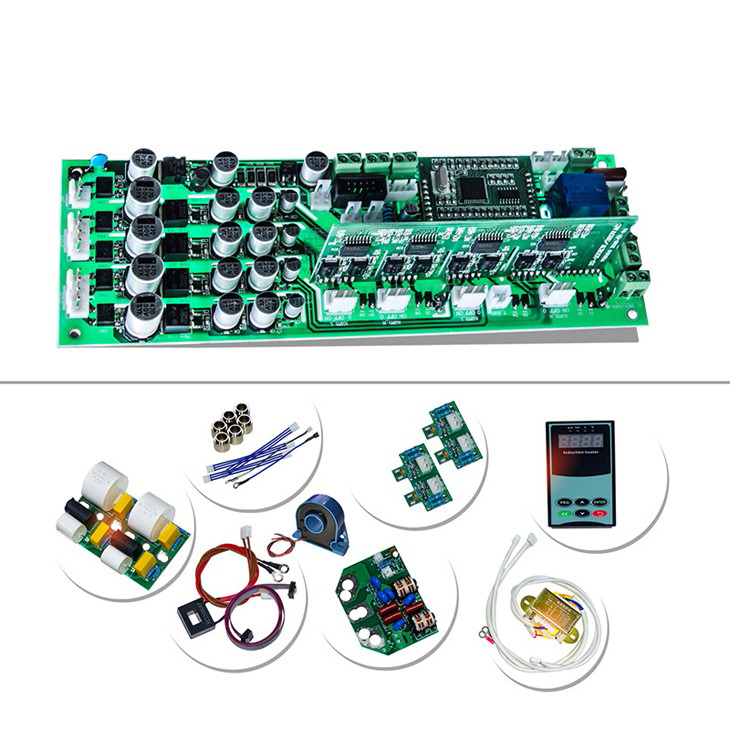

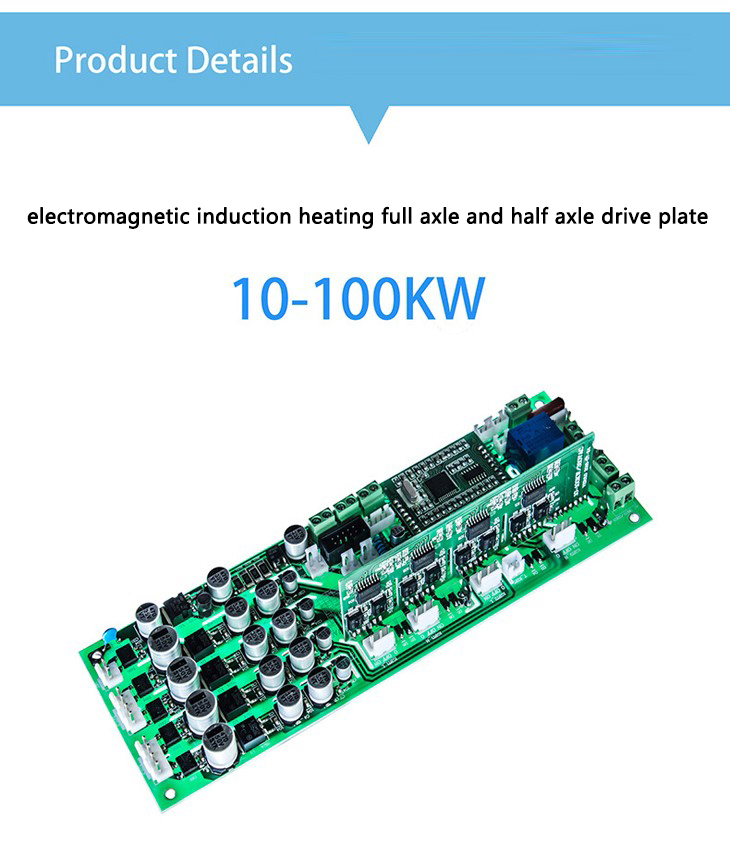

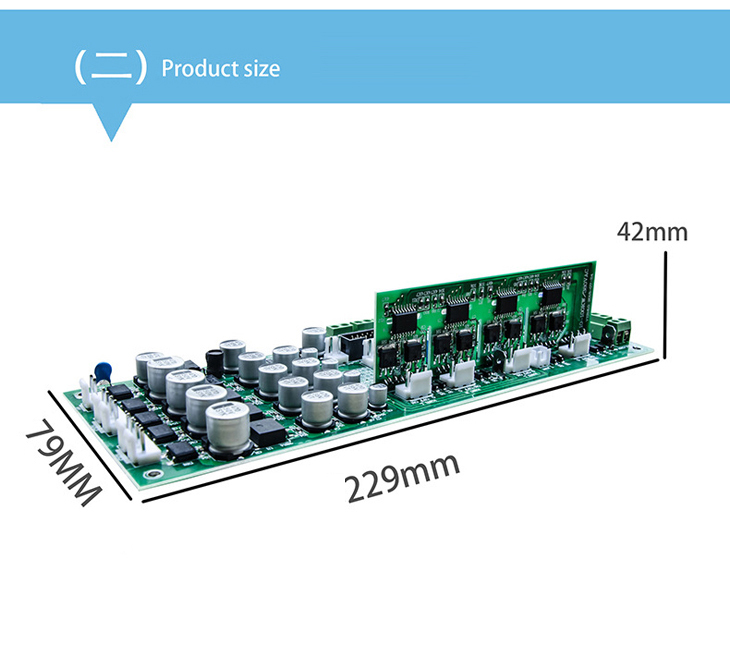

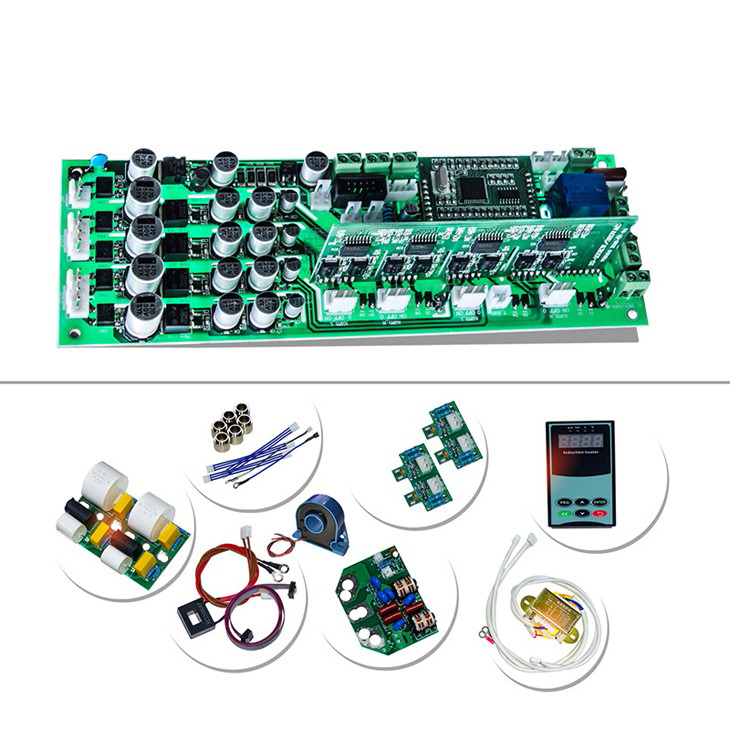

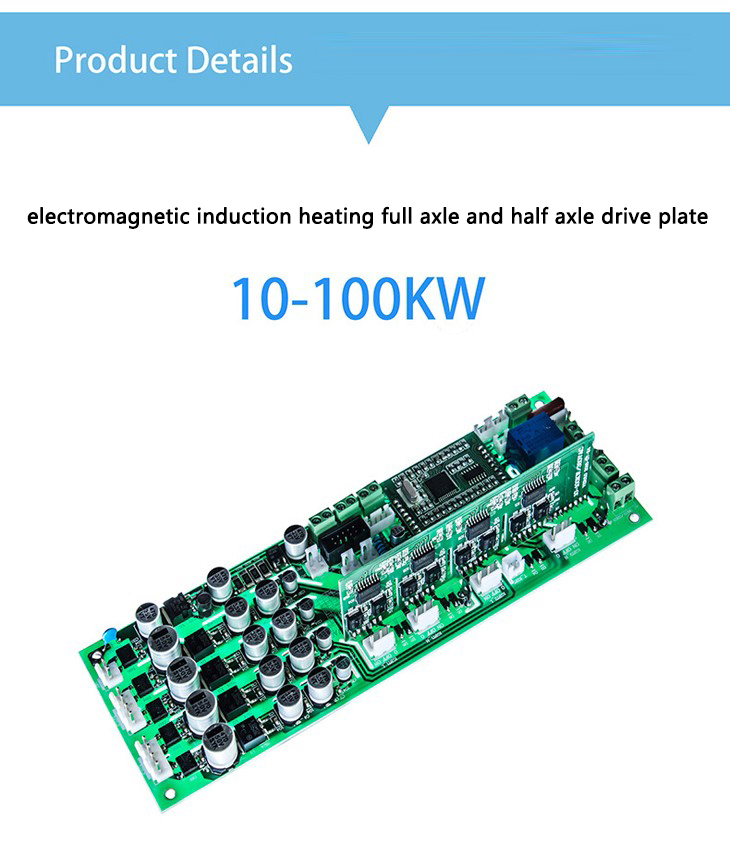

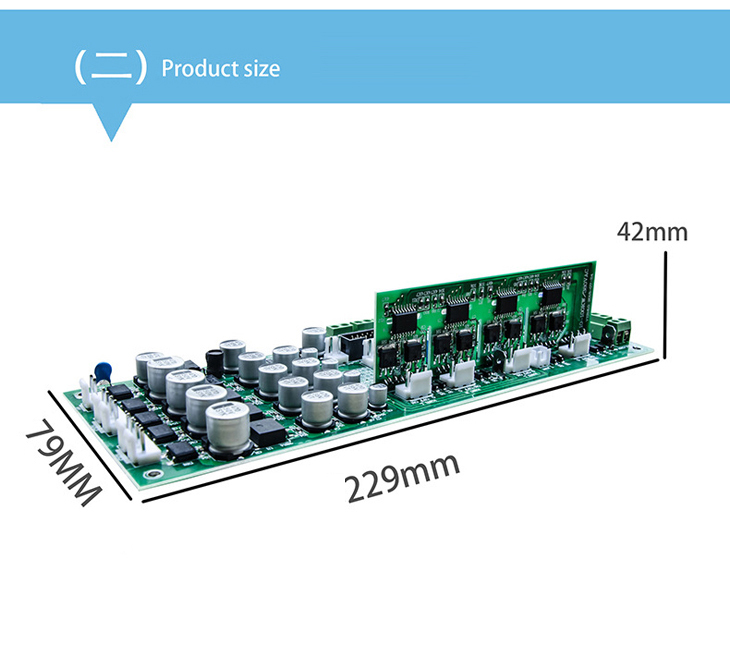

1-100kw Electromagnetic Induction Half-axle Drive Plate

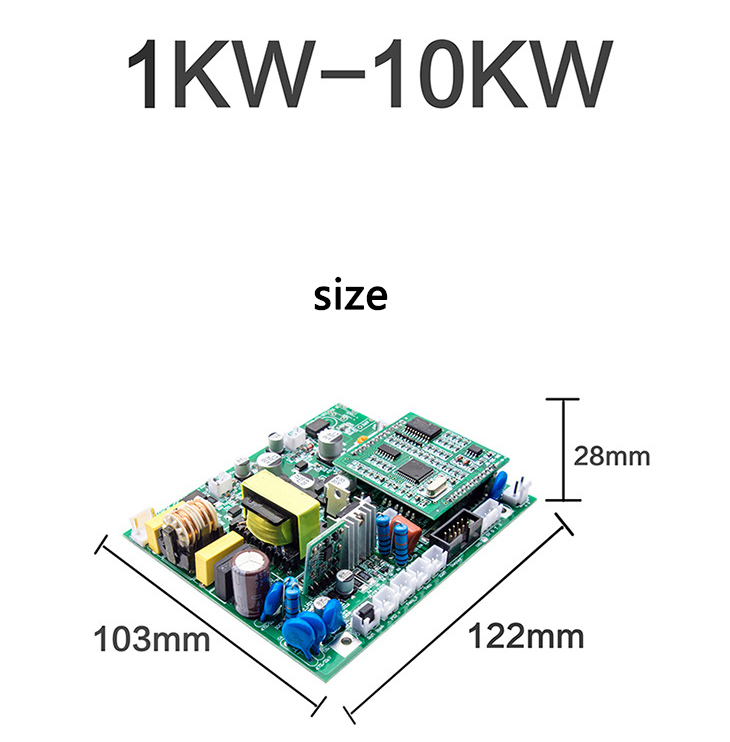

ated power: 1kW ~ 100kW

Rated voltage and frequency: 220V / 380V

Voltage applicable range: 220V ~ 380V

Applicable ambient temperature: - 20 ~ 40 ° C

Applicable ambient humidity: ≤ 95%

Power regulation range: 20% ~ 100%

Heat conversion efficiency: ≥ 99%

Effective power: 1kW ~ 100kW

Operating frequency: 50Hz / 60Hz

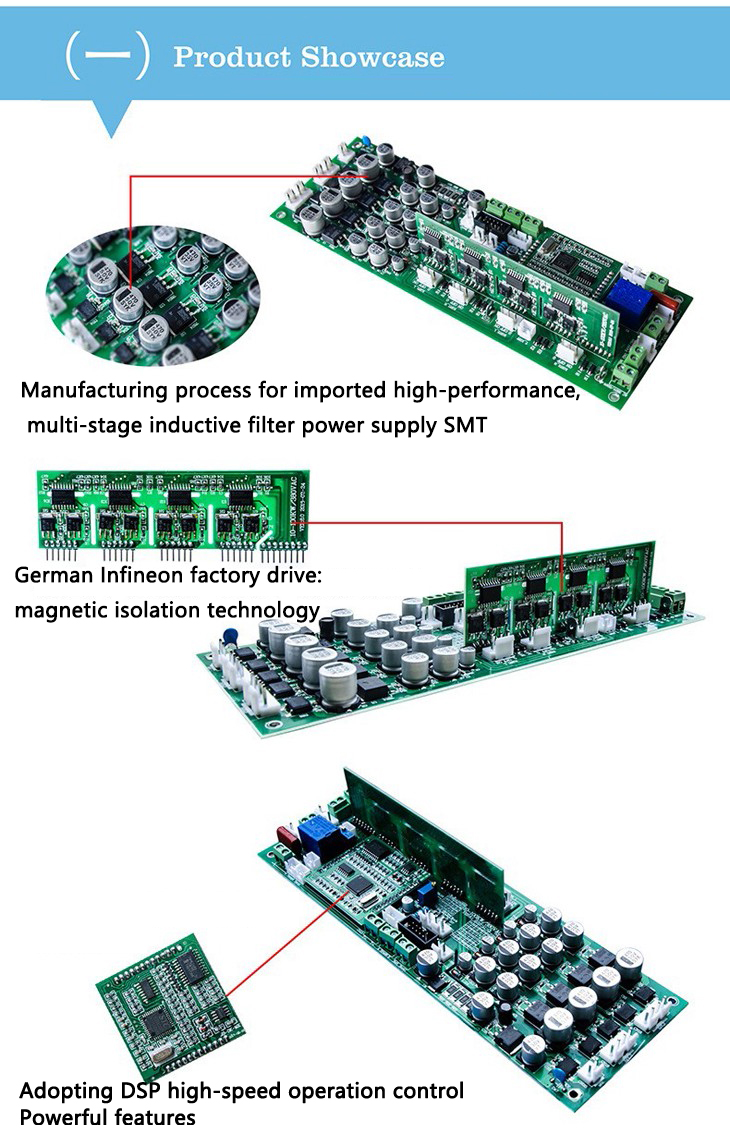

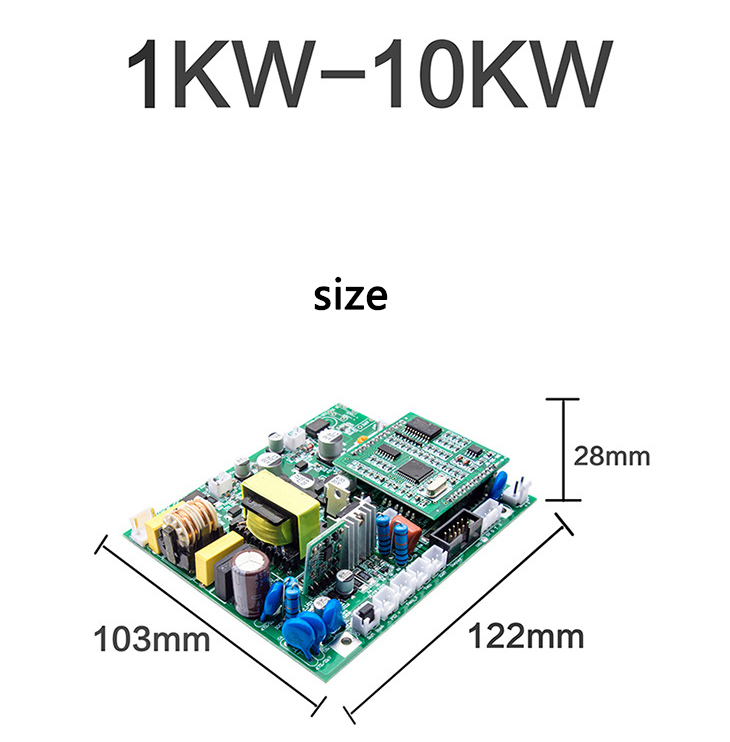

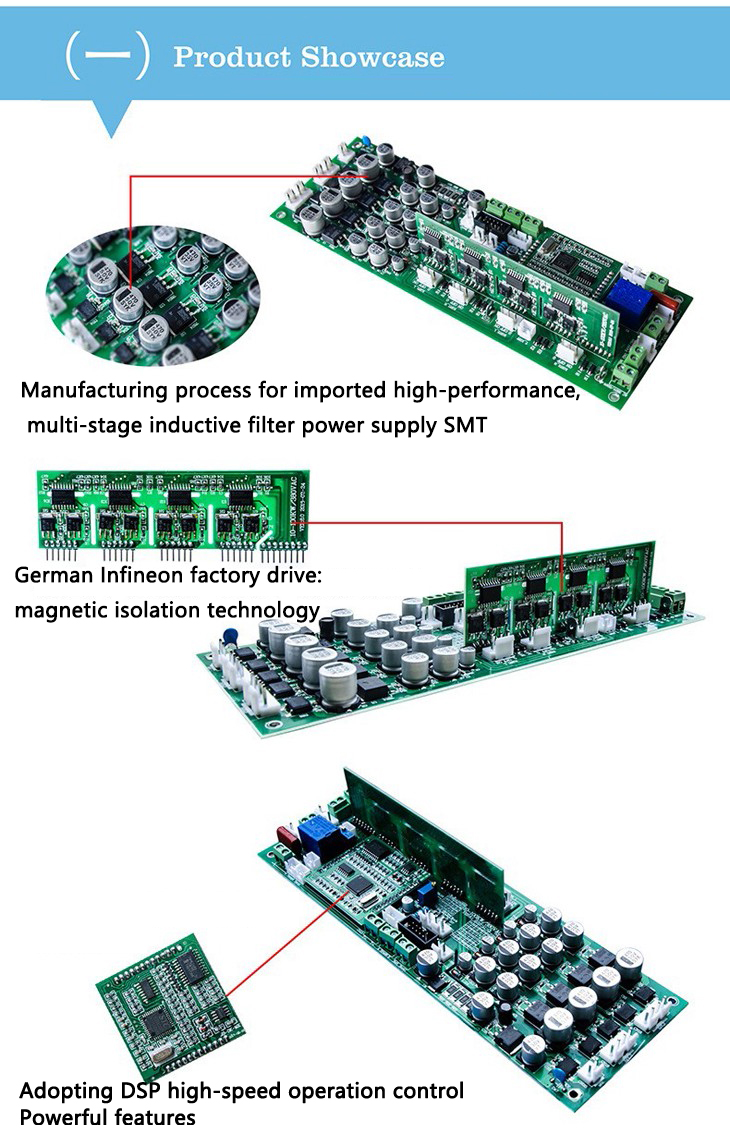

The single-phase half bridge 1kW ~ 10kW or three-phase full bridge / half bridge 5kW ~ 30kW electromagnetic heating drive board can be applied to a simple electromagnetic heating system, can also be equipped with an automation system, and an industrial 485 bus communication interface with the computer is reserved to meet the interface requirements in automation control. For single phase, it can be applied to 1 ~ 10kW electromagnetic heating drive, and can drive 150A / 1200V IGBT at most. For three phases, it can be applied to 5 ~ 30kW full axle / half axle electromagnetic heating drive, and can drive 450A / 1200V IGBT at most It integrates all digital core controller and IGBT Driver. Only IGBT module, rectifier bridge, resonant capacitor, radiator and other devices can be added to form a high-performance electromagnetic induction heating system

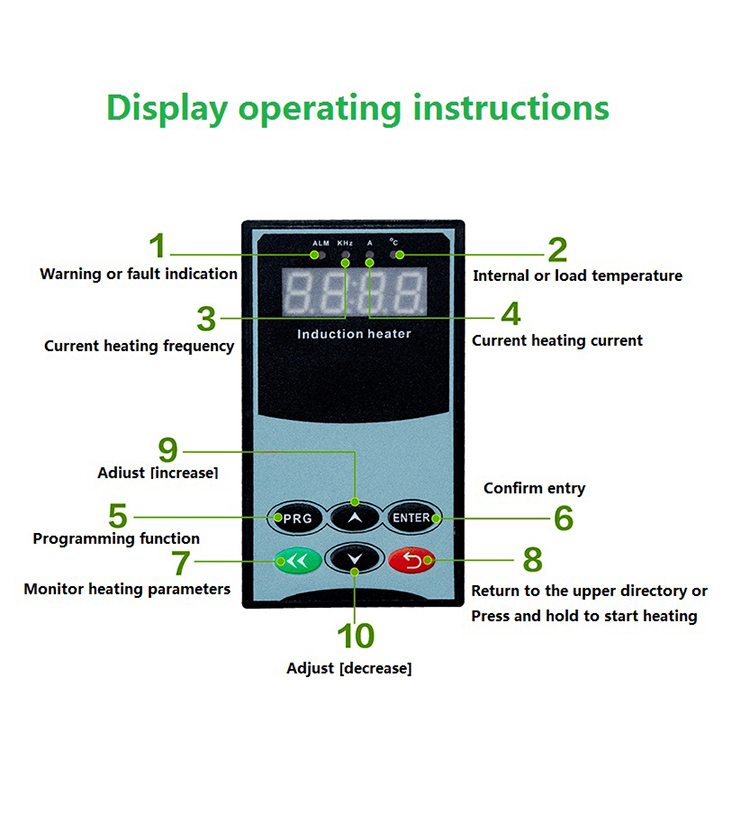

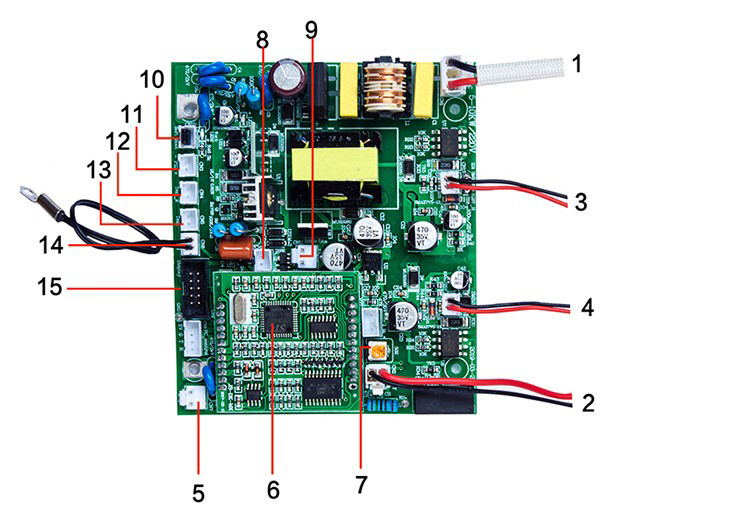

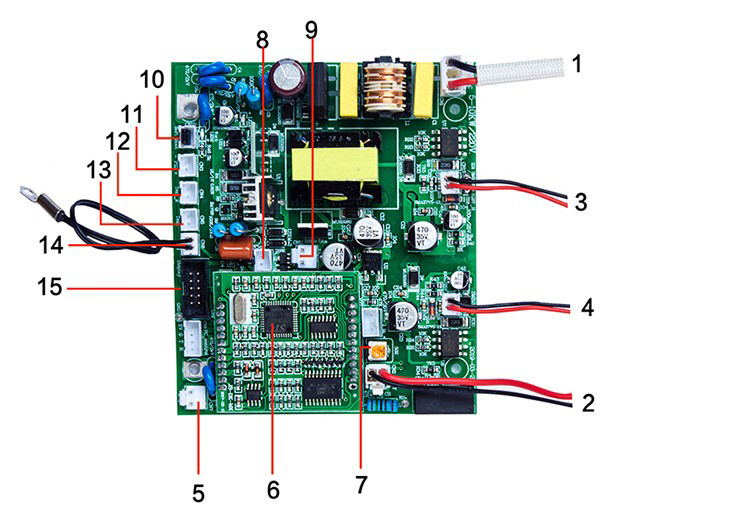

1. Connect power supply 220V

2 Transformer connection lines

3-4. Interface of IGBT

5. RS485 communication interface, Modbus RTU standard communication protocol

6. High speed automatic phase-locked tracking control system based on DSP

7. Power adjustment of potentiometer

8. External 24V working indicator light, constantly on during operation and flashing when not in operation

9. External 0.3A/24V DC fan interface

10. Soft start interface, close start, disconnect stop.

11. The external 10k potentiometer or 0-5V input or 4-20mA interface can be set through (F-22).

12. External load temperature detection interface 2, with an accuracy of up to 1℃

13. External load temperature detection interface 1, with an accuracy of up to 1℃. When using a single channel, default 1 is used to measure the external working temperature

14. IGBT temperature detection interface

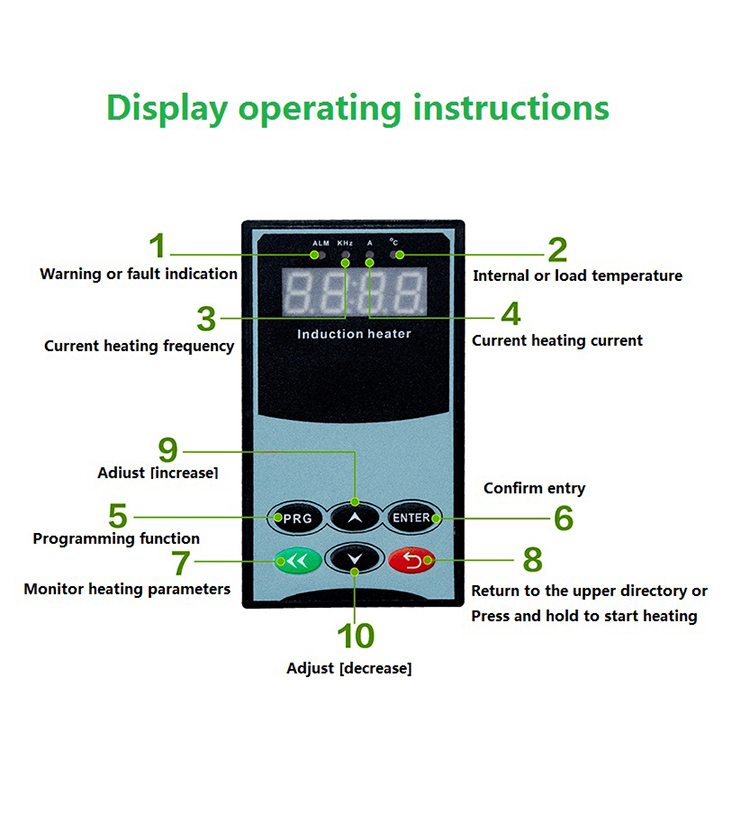

15. External programmable operation display

Integrated with a fully digital core controller and IGBT driver, an electromagnetic heating system can be assembled by adding only IGBT modules, rectifier bridge stacks, resonant capacitors, heat sinks, and other components externally.

Suitable for single-phase 1-10KW electromagnetic heating drive, with a maximum drive of 150A/1200V IGBT

It can be applied to simple electromagnetic heating systems and can also be matched with automation systems, with reserved industrial 485 bus and computer communication interfaces to meet the interface requirements in automation control.