100kW-200kW High Power Electromagnetic Induction Heating Driving Plate

Rated power: 10kW ~ 200kW

Rated voltage and frequency: 380V / 50Hz / 60Hz

Voltage adaptation range: 380V ± 20%

Applicable ambient temperature: - 20 ~ 40 ° C

Applicable ambient humidity: ≤ 95%

Power regulation range: 20% ~ 100%

Heat conversion efficiency: ≥ 99%

Effective power: 10kW ~ 200kW

Operating frequency: 5 ~ 40KHz

In order to meet the demand of higher power, 100kW ~ 200kW driver is introduced, which can drive 4 ~ 6 450A / 1200V modules, with power up to 160 ~ 200kW. It can also be downward compatible. It can be used as 10-100kw series driver. It adopts dual core high-speed processor and German Infineon drive chip to reach the best working state, with built-in 0-5V, 0-10V, 4-20mA, RS-485 communication, 4-channel temperature, multi-channel programmable input 2-way programmable relay output, steam control system and other control functions. It can be widely used in high-power boilers, steam, heat transfer oil, large pipelines and reactors.

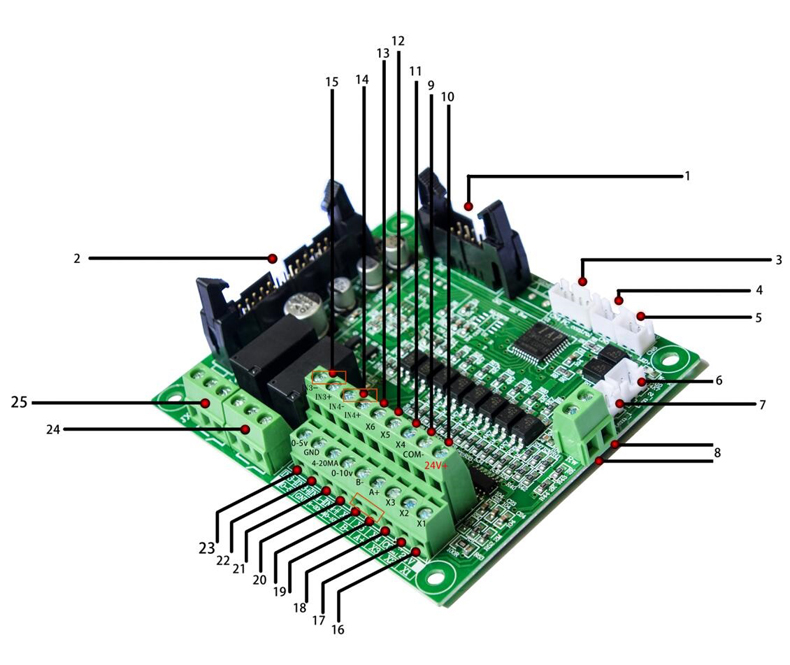

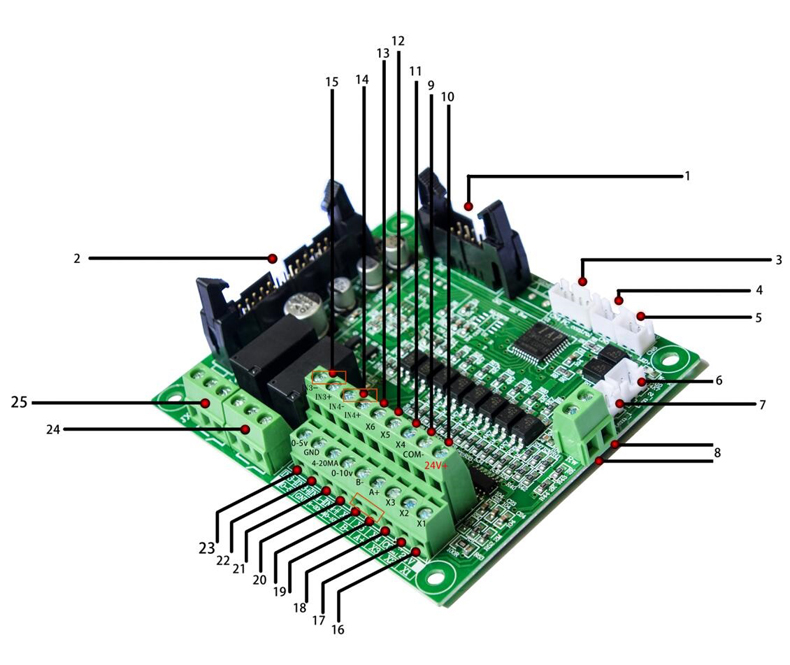

1. Connect the monitor

2. Connect to the main control board

3. Connect the computer PC

4. Connected control (connected to the starting terminal of the next machine)

5. External 24V LED indicator light

6. Load 2nd temperature detection (thermistor, measurement range: 0-200 ° C)

7. Load 1st temperature detection (thermistor, measurement range: 0-200 ° C)

8. External 10K adjustable resistor (F-02 needs to be set to 01), adjust the power size

9.24V power supply (COM), also a common terminal for the input startup terminal

10.24V power supply+24V

11. X4, input terminal (when F-02 is set to 05, X4 and COM work at 30% power when closed)

12. X5, input terminal (when F-02 is set to 05, X5 and COM work at 60% power when closed)

13. X6, works when the input start terminal is closed with the COM terminal, and stops when it is disconnected

14. Load 4th temperature detection (thermocouple, measurement range: 0-1023 ° C)

15. Load 3rd temperature detection (thermocouple, measurement range: 0-1023 ° C)

16. X1, the input terminal and COM are closed to indicate low water level

17. X2, input terminal and COM closed for medium water level indication

18. X3, input terminal and COM closed for high water level indication

19. External upper computer or touch screen, AB line, to achieve remote control

20.0-10V input terminal, with input 0-10V voltage control power between GND (F-02 set to 3)

21.4-20mA input terminal, between GND is the input 4-20mA voltage control power (F-02 is set to 4)

22. GND

23.0-5V input terminal, and between GND is the input 0-5V voltage control power (F - set to 2)

24. Fault output, disconnected during normal operation, closed when a fault occurs

25. For pre programmable output