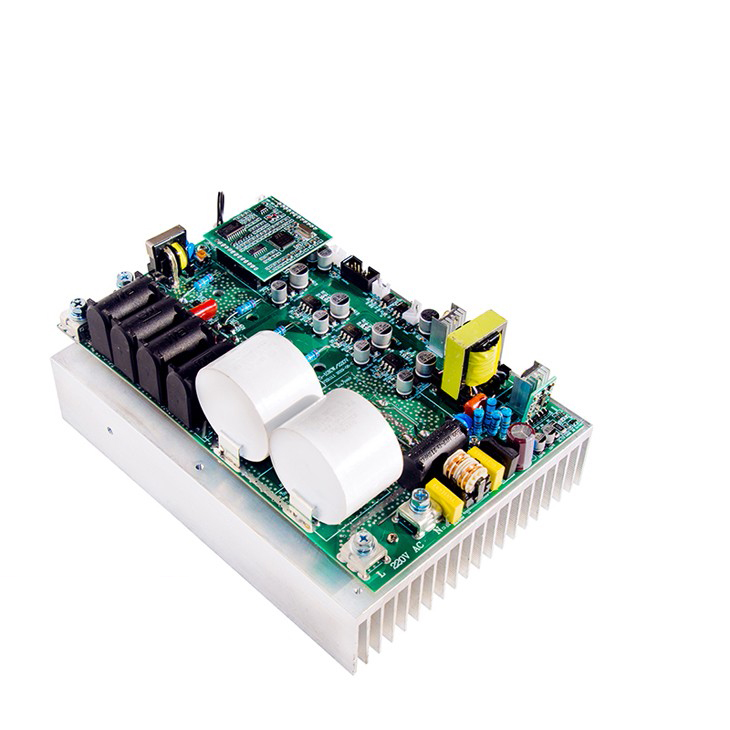

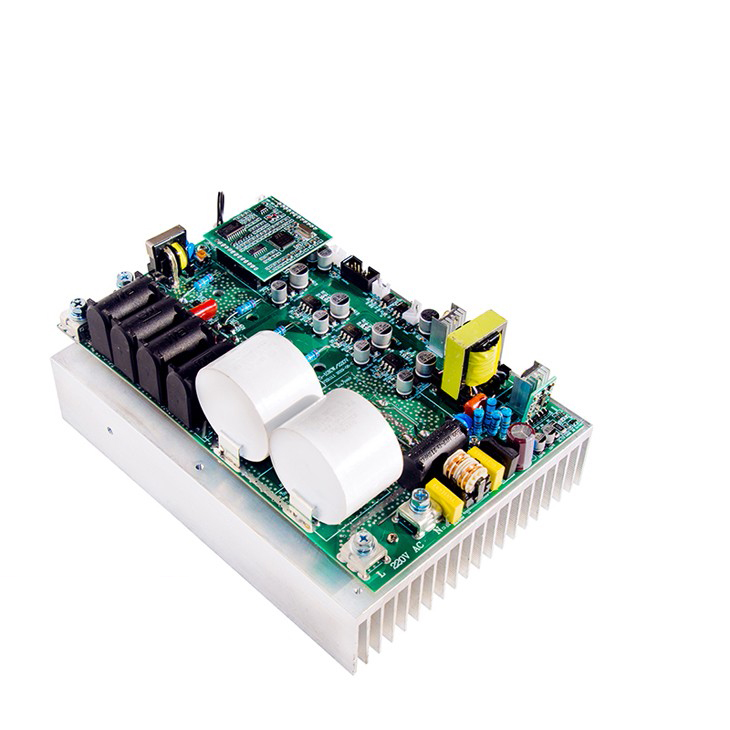

Single Phase Full Bridge 8kw Electromagnetic Heating Control Board

1、 Basic structure

The single-phase full bridge 8kW electromagnetic heating control board mainly consists of a main control chip, IGBT transistor, driver board, thermistor, etc. The main control chip is the "brain" of the entire control board, responsible for receiving external instructions and controlling the switching status of IGBT tubes, thereby generating electromagnetic fields. Thermistors are used to detect the working temperature of the heating plate and feedback the signal to the main control chip, forming a closed-loop control.

2、 Working principle

When the control board receives a startup command, the main control chip will control the switching frequency of the IGBT tube through PWM (Pulse Width Modulation) technology based on the set heating temperature. When the IGBT tube is in a conductive state, the current will heat the food through the heating plate; When the IGBT tube is disconnected, the current is interrupted, and the surface of the food is no longer affected by the magnetic field, preventing food from burning.

3、 Application scenarios

The single-phase full bridge 8kW electromagnetic heating control board is widely used in commercial induction cookers, household induction cookers, ceramic ovens, microwave ovens and other household appliances. It has the advantages of high heating efficiency, energy conservation and environmental protection, safety and reliability, and is an important component of modern household appliances.

4、 Common problems and solutions

IGBT tube damage: may be caused by overvoltage, overcurrent, and other reasons. After replacing the new IGBT tube, it is necessary to ensure circuit safety and avoid further damage.

Temperature sensor abnormality: After replacing the new temperature sensor, parameter adjustment is required to ensure the normal operation of the control board.

Unable to start: It may be a power issue or a malfunction of the control board itself. It is necessary to check if the power supply is normal. If there is a problem, the control board needs to be replaced.

Rated power: 8kw

Rated voltage frequency: 220V / 50Hz

Voltage applicable range: 160V ~ 260V

Applicable ambient temperature: - 20 ~ 50 ℃

Applicable ambient humidity: ≤ 95%

Power regulation range: 20% ~ 100%

Heat conversion efficiency: ≥ 98%

Effective power: 100%

Operating frequency: 5 ~ 40KHz

Industrial design has beautiful appearance and large area thermal design. It is especially suitable for heating equipment, commercial induction cooker and other occasions with large industrial heating area requirements. It has the characteristics of low voltage and high power. In some occasions, it does not have three-phase power supply, which is comparable to three-phase 8kw electromagnetic heater to a certain extent. It adopts the fifth generation digital processing platform technology of the company, with powerful function and stable performance. It is an ideal product for small and medium-sized heating equipment.

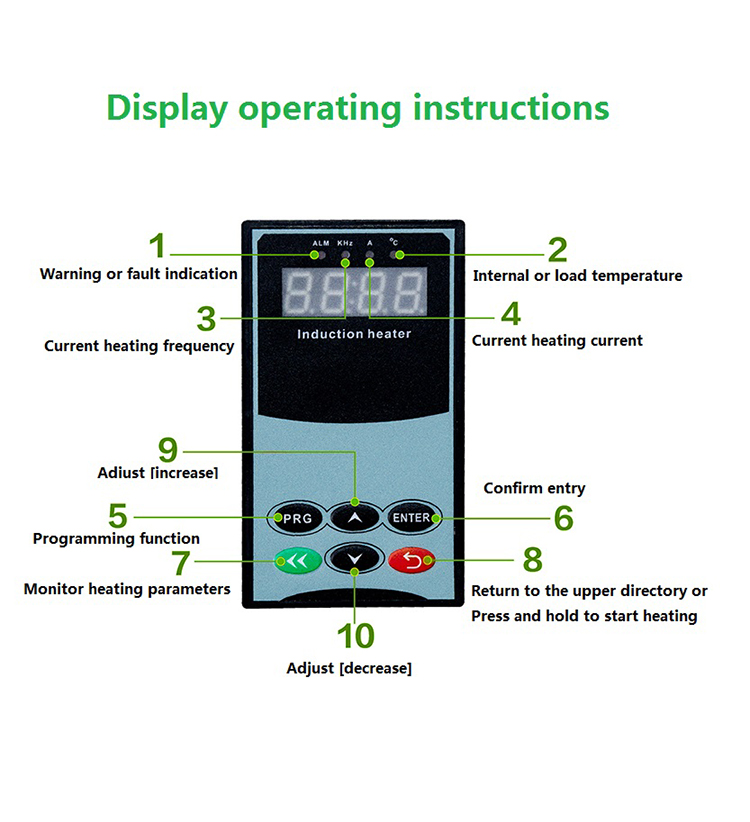

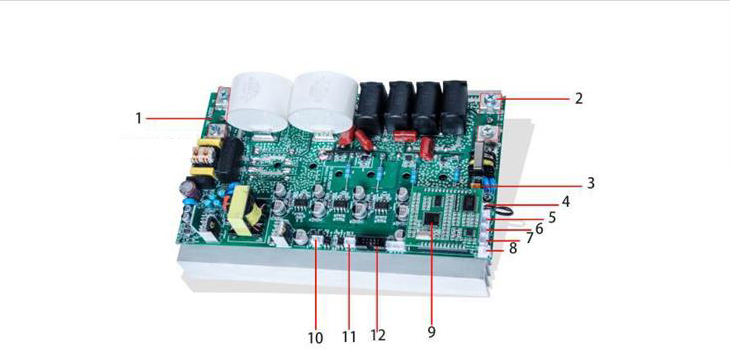

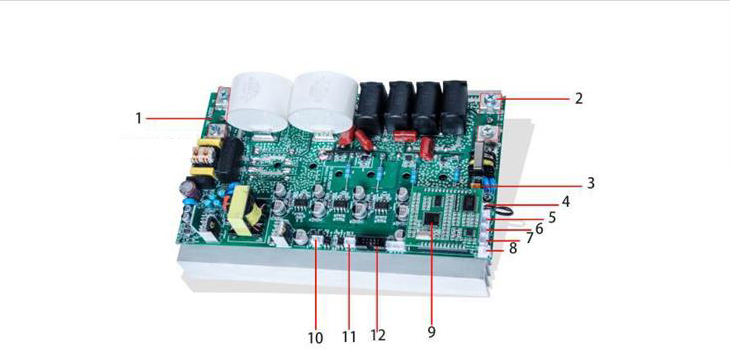

1.220V power supply

2. Wiring ring

3. Power adjustment of potentiometer

4. IGBT temperature detection interface

5. External load temperature detection interface 1, with an accuracy of up to 1 ℃ for single channel measurement, defaults to 1 for measuring external working temperature

6. External load temperature detection interface 2, with an accuracy of up to 1 ℃

7. Multifunctional input interface (set through F-20)

8. Transformer connection line

9. High speed automatic phase-locked tracking control system based on DSP

10. External 03A/24V * 1 DC fan interface

11. Soft start interface

12. External programmable operation display